CATEGORIES

- Architecture (21)

- Exporting and Paperwork (9)

- Exports (5)

- Exteriors (3)

- Flooring (21)

- Interiors (10)

- Landscape (3)

- News (8)

Close

Picture this: You’re standing in your Toronto warehouse, inspecting a fresh shipment of porcelain tiles. They look perfect. The marble veining is crisp. The dimensions are spot-on. The finish is exactly what your customer prefers.

But how did these tiles get here? What happened between the factory in India and this moment?

If you’re a Canadian importer considering Indian tile sources, understanding this journey matters. Not just the “what” but the “how” and “why” behind each step.

This guide walks you through the complete porcelain tile export from India to Canada process, from raw clay to your loading dock. We’ll cover what actually happens, why it matters, and what you should look for at each stage.

Before diving into logistics, let’s talk about why Canadian buyers are increasingly looking at Indian tiles.

The numbers tell part of the story. India shipped over 589 million square meters of ceramic tiles globally in 2023, making it the world’s second-largest tile exporter. But numbers only explain so much.

The real story is about evolution. Indian tile manufacturing has transformed dramatically over the past decade. Factories that once produced basic tiles now operate Italian presses and digital printing systems. Quality control that was inconsistent is now rigorous and documented.

For Canadian buyers, this means access to products that perform like European tiles but without European price tags. You’re typically looking at 25-35% cost savings while still meeting Canadian building code requirements.

That combination, quality plus value, is why the porcelain tile export from India to Canada process is becoming routine rather than exceptional.

Most Indian tiles start in Morbi, Gujarat, India’s answer to Italy’s Sassuolo. About 90% of India’s tiles come from this region where hundreds of factories operate within a concentrated area.

This clustering creates efficiency. Raw material suppliers are nearby. Specialized equipment manufacturers operate locally. When Canadian buyers place orders, manufacturers source everything quickly. Production moves faster. Costs stay competitive.

Here’s what surprises Canadian buyers visiting Indian factories: the equipment looks familiar.

Italian Sacmi presses. Digital printing systems from manufacturers supplying European factories. Modern kilns with precise temperature controls. Indian manufacturers invested heavily because global markets demanded it.

The process starts with the right clay mixture. It gets pressed under enormous pressure, then fired at temperatures exceeding 1,200°C. This transforms clay into dense, water-resistant porcelain.

After firing, different treatments create final products, matte coatings, glossy glazes, digital printing for stone or wood effects, and textured surfaces.

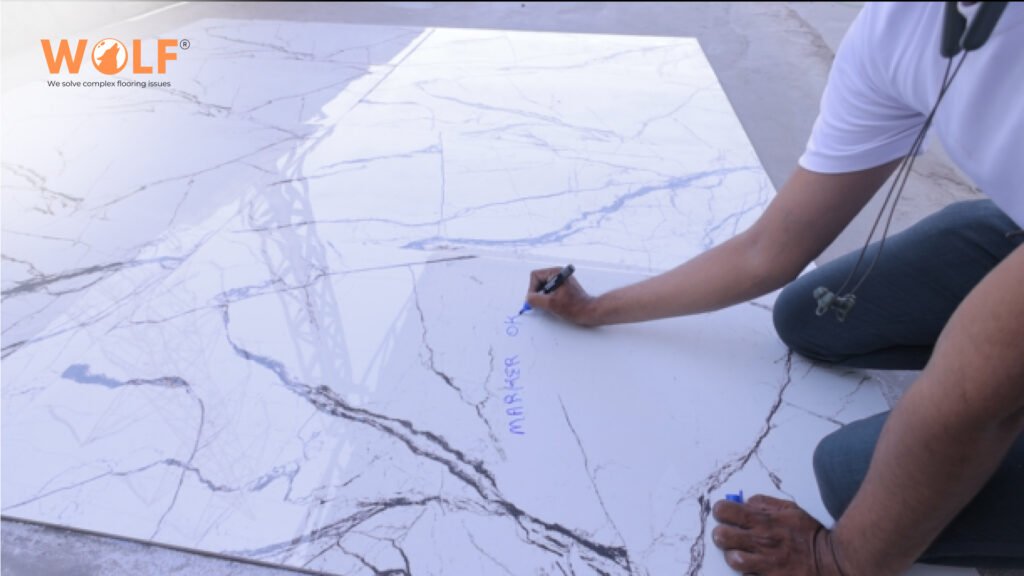

This might be the most important section. You need confidence before tiles leave India, not after they arrive with problems.

Good manufacturers establish exact requirements first. Dimensions and tolerances, Colors and patterns, Surface finish and Technical specifications.

These details get documented. Production teams work from these specs. Quality inspectors test against them.

Quality control is continuous. Raw materials get tested before mixing. Kiln temperatures get monitored constantly. Dimensions get measured during production. Surfaces get inspected for defects.

Before tiles enter export packaging, comprehensive testing happens:

Water Absorption: Porcelain must absorb less than 0.5% water. That prevents freeze-thaw damage in Canadian winters and moisture problems in bathrooms.

Breaking Strength: Tests apply specific pressure measuring how much tiles withstand before breaking. Good manufacturers exceed Canadian building code requirements.

Surface Quality: Inspectors examine every tile for chips, cracks, glaze defects, or color inconsistencies.

Batch Consistency: Quality control compares batches ensuring colors match and patterns align.

Your shipment arrives with actual test reports, specific measurements from your actual tiles, not generic claims.

Tiles are fragile and heavy. Proper packaging prevents containers arriving with significant damage.

Each tile gets separated with foam, cardboard, or protective film. Heavy-duty cartons designed specifically for tile weight contain protected tiles. Pallets organize boxes with proper weight distribution, heavier boxes bottom, lighter top.

A 20-foot container typically holds 800-1,400 square meters depending on thickness. Heavier pallets go front and rear for weight distribution. Airbags or bracing fill gaps preventing movement during ocean transport.

Everything gets documented. Detailed packing lists show exactly what’s in each box on each pallet.

Morbi sits about 100 kilometers from Mundra Port, India’s largest commercial port. This proximity keeps the porcelain tile export from India to Canada process efficient.

Vancouver: Serves Western Canada with shortest transit, typically 25-35 days.

Montreal: Eastern Canada’s entry point. Transit runs 30-40 days via the Suez Canal or transshipment hubs.

Toronto and Hamilton: Great Lakes access for interior Canadian distribution.

International shipping requires comprehensive paperwork. Commercial invoices detail what you’re importing. Packing lists itemize container contents. Bills of lading serve as shipping contracts. Certificates of origin verify Indian manufacturing. Insurance certificates document coverage.

Proper documentation prevents customs delays. Missing paperwork can hold shipments for weeks.

Your tiles arrive at a Canadian port and go through customs clearance.

Tiles fall under specific HS codes determining duty rates. HS Code 6907 covers ceramic tiles. HS Code 6908 covers porcelain or vitrified tiles.

Import duties apply based on classification and origin. Canadian GST or HST applies depending on provincial destination. Your customs broker calculates total costs and handles payments.

Customs reviews documentation, assesses duties and taxes, sometimes physically inspects shipments. Once everything checks out and fees are paid, customs releases your cargo. Most clearances complete within 2-7 days.

After customs clearance, tiles move to final destinations.

Trucking handles most deliveries from ports to interior locations. Temperature control isn’t needed, but careful handling remains essential.

Rail offers cost-effective options for Western Canada. Full containers move from Vancouver to interior provinces efficiently.

Warehousing lets some importers receive containers at distribution centers near ports for inventory management.

From order placement to Canadian delivery (typical timelines):

Total: 8-12 weeks from order confirmation to delivery.

The porcelain tile export from India to Canada process works smoothly with the right manufacturer.

Look for export experience with North American shipments. Communication quality that’s responsive without prompting. Quality systems that are documented and verifiable. Production capacity matching your volumes reliably.

Professional manufacturers handle logistics comprehensively. They coordinate freight forwarders, prepare export documentation correctly, supervise container loading, provide tracking updates, and support post-delivery issues.

Plan for 8-12 weeks total from order placement to delivery, including manufacturing (2-4 weeks), ocean shipping (25-40 days), customs clearance (2-7 days), and inland transport (1-7 days).

Vancouver serves Western Canada with shortest transit (25-35 days). Montreal serves Eastern Canada (30-40 days). Toronto and Hamilton provide Great Lakes access for central distribution.

Porcelain tiles should test below 0.5% water absorption. Breaking strength must meet load requirements. Dimensional accuracy ensures proper installation. Request documented test reports verifying specifications.

Individual tiles receive protective layering. Heavy-duty cartons contain protected tiles. Pallets organize boxes with proper weight distribution. Containers use bracing systems preventing movement during transit.

Essential documents include commercial invoice, packing list, bill of lading, certificate of origin, insurance certificate, and quality test reports.

Yes, though most require full or partial container loads. Some manufacturers accommodate smaller initial shipments. Mixed containers allow testing different products.

Indian porcelain tiles typically cost 25-35% less than comparable European products while maintaining quality through modern manufacturing and rigorous quality control.

Wolf Porcelain Tiles has spent two decades perfecting the porcelain tile export from India to Canada process. We manufacture premium collections using advanced Italian technology with quality control Canadian buyers require.

Product Range: Large-format options from 60×120cm to 120×180cm. Stone-look effects. Wood-grain designs. Contemporary neutrals. Custom solutions for specific requirements.

Quality Assurance: Testing for water absorption below 0.5%. Breaking strength exceeding Canadian requirements. Dimensional accuracy for precise installation. Documented results with every shipment.

Complete Export Support: Production coordination. Quality verification before shipping. Documentation preparation. Shipping arrangement. Post-delivery support.

Canadian Market Knowledge: We understand your building codes, customs procedures, logistics considerations, and timeline pressures.

Communication stays transparent from initial inquiry through final delivery. You’ll know what’s happening at each stage.

Contact us to discuss how our manufacturing capabilities and export experience can support your Canadian business with quality products, reliable timelines, and professional service.

Wolf Porcelain Tiles

Product information: wolfporcelaintiles.com

Canadian inquiries: info@wolfgroupindia.com